Description

Clevis Hanger Making Machine | Precision Pipe Support Fabrication

Clevis hangers come in various sizes to accommodate different pipe diameters and applications. Here are some of the sizes available:

B3100 series: Standard clevis hanger with a Slide-Rite design, allowing for a 15-degree swing in either direction

B3100C series: Standard plastic coated clevis hanger designed for steel or other pipe types of the same

B3100F series: Standard felt lined clevis hanger designed for the suspension of copper tube to prevent electrolysis.

B3104 series: Light-duty clevis hanger recommended for the suspension of light stationary pipe, available in felt-lined and PVC-coated options.

B3104CT series: Clevis hanger for non-insulated stationary copper tubing lines, available with PVC coating.

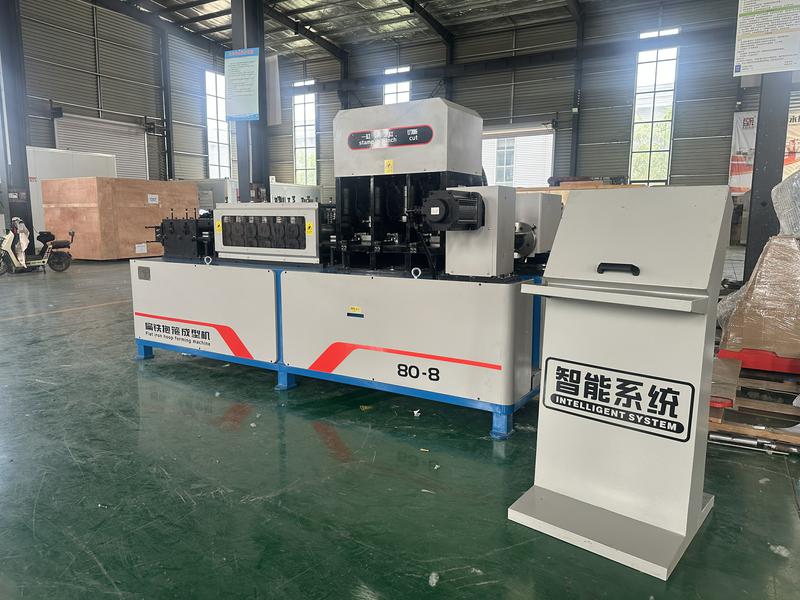

What Is a Clevis Hanger Making Machine?

A clevis hanger making machine is a specialized piece of equipment used in the manufacturing of clevis hangers—U-shaped pipe support devices used in plumbing, HVAC, and industrial piping systems. This automated machine streamlines the entire process, from metal feeding and cutting to punching and forming, ensuring consistent quality and fast output.

Key Features of Our Clevis Hanger Machine

Automatic Feeding & Forming – Fully automated process with programmable settings for different sizes.Heavy-Duty Construction** – Built for continuous operation in industrial environments.

High Precision – Accurate shaping and punching for consistent product quality.

Custom Tooling Options** – Adaptable molds for different clevis hanger sizes and shapes.

Compact Design – Space-saving layout with user-friendly interface.

Specification of clevis hanger making machine

| Model | GST50-5 | GST60-6 | GST80-8 |

| Power | 7.5kw | 11.5kw | 15.5kw |

| Material thickness | 1-5mm | 2-6mm | 4-8mm |

| Material width | 10-50mm | 20-60mm | 30-80mm |

| Weight | 1600kgs | 2000kgs | 2900kgs |

Applications of clevis hanger making machinne

Clevis hangers are widely used in:

Industrial Pipelines,HVAC Systems,Plumbing Installations,Mechanical & Utility Systems

Why Choose Our Clevis Hanger Production Line?

1.Fully Automated Workflow

2.Reduces labor costs and boosts productivity.

3.Export-Ready Machine – CE certified with international standards compliance.4.After-Sales Support – Remote setup assistance, video guides, and spare parts.

5.Durability Guaranteed – Long-lasting components and steel frames.

6.Flexible Mold Change System – Quick switch between clevis sizes and types.

Optional Add-device

Automatic DecoilerHydraulic Punching Station

Servo Feeder System

Mold Sets for Different Sizes

PLC Upgrade with Memory Functions

Frequently Asked Questions

Q1: Can the machine make different clevis hanger sizes?Yes, we offer mold sets for small, medium, and large clevis hangers.

Q2: What materials can be used?

You can use galvanized steel, carbon steel, or stainless steel with suitable thickness.

Q3: How much does the machine cost?

Price depends on configuration and output capacity.

Contact us for more information